Close

3D-printed and wet metallized sensors

The work is carried out in the framework of the interdepartmental laboratory MEMS&3D of Politecnico di Milano, Italy.

People involved: V. Zega, C. Credi, M. Invernizzi, R. Bernasconi, G. Langfelder, R. Suriano, F. Cuneo, A. Cigada, M. Levi, L. Magagnin, A. Corigliano

A new fabrication process for sensors

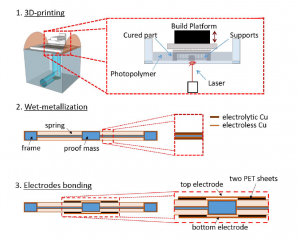

A two-step fabrication process obtained by properly combining the stereolithography 3D-printing and the wet-metallization techniques is proposed. External rigid frames are added to the fabricated structures to provide the anchor points at the end of the suspending springs and to allow the bonding of Cu electrodes for capacitive sensing.

z-axis accelerometers

Three accelerometers are designed to electrostatically measure the external acceleration acting along the out-of-plane (z-) direction. They consist of one proof mass suspended through two springs (Figure 1). Two electrodes, above and beneath the proof mass, allow the electrostatic differential readout.

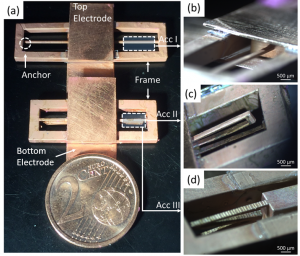

Figure 1: images showing the overall dimensions of 3D printed z-axis accelerometers after wet metallization and electrodes assembly. (a) High-magnification insets show the three different designs studied with elongated (b) and folded (c and d) suspending springs.

Figure 1: images showing the overall dimensions of 3D printed z-axis accelerometers after wet metallization and electrodes assembly. (a) High-magnification insets show the three different designs studied with elongated (b) and folded (c and d) suspending springs.

Experimental measurements show a very good agreement with theoretical predictions thus proving a good reliability of the proposed design flow and fabrication process. With their relative small footprints (minimum dimension in the order of hundreds of µm), good performances (sensitivity >12 fF/g, sub % linearity error up to 11 g of full scale and theoretical noise estimation of few tens of ng/√Hz) and high customizability, they represent an important step toward novel application fields of inertial sensors.

Bibliography:

[1] V. Zega, C. Credi, R. Bernasconi, G. Langfelder, L. Magagnin, M. Levi and A. Corigliano ‘The first 3D-printed z-axis accelerometers with differential capacitive sensing’ IEEE Sensors Journal 18 (2018) 53- 60

[2] C. Credi, V. Zega, R. Bernasconi, G. Langfelder, A. Cigada, L. Magagnin, M. Levi, A. Corigliano ‘Design, fabrication and testing of the first 3D-printed and wet metallized z-axis accelerometer’ Proceedings, 1, 614, doi:10.3390/proceedings1040614 (2017) 1-5

[3] V. Zega, C. Credi, M. Invernizzi, R. Bernasconi, G. Langfelder, A. Cigada, L. Magagnin, M. Levi and A. Corigliano ‘3D-printing and wet metallization for uniaxial and multi-axial accelerometers’ Eurosime 2018, Toulouse, France, April 15-18, 2018

3-axis accelerometers

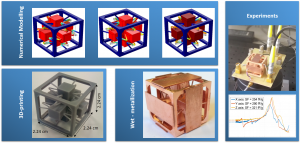

A 3D-printed and wet-metallized three-axis accelerometer is also proposed. Thanks to the three-dimensionality of the printing process, a central symmetry along the three axes can be obtained by design, unlike in common 2D-like microfabrication processes. Electrostatic differential sensing is obtained through the metallization procedure and the subsequent mounting of fixed electrodes on an external frame of the mechanical structure.

Experimental tests under accelerations show good agreement with theoretical predictions.

With relatively small dimensions (features as low as 450 µm), very high capacitive sensitivity (> 200 fF/g) and low theoretical thermo-mechanical noise, the proposed three-axis accelerometer represents a further step towards the development of an innovative fabrication process for high-performance, customizable and low cost electro-mechanical devices.

Bibliography:

[1] V. Zega, M. Invernizzi, R. Bernasconi, F. Cuneo, G. Langfelder, L. Magagnin, M. Levi, A. Corigliano ‘The first 3D-printed and wet-metallized three-axis accelerometer with differential capacitive sensing’ IEEE Sensors Journal, 19 (20) (2019) 9131-9138.

Experimental test on a 3D-printed and wet-metallized z-axis accelerometer

Experimental setup. The PCB with the fabricated accelerometer is mounted on a shaker in a vertical direction in order to avoid offsets due to gravity. The reference accelerometer for closed-loop control is mounted opposite to the accelerometer under test, on the other side of the board.